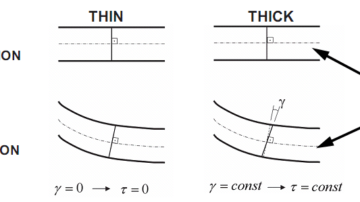

Shell problems generally fall into one of two categories: thin shell problems and thick shell problems. Thick shell problems assume that the effects of transverse shear deformation are important to the solution. Thin shell problems, on the other hand, assume that transverse shear deformation is small enough to be neglected.

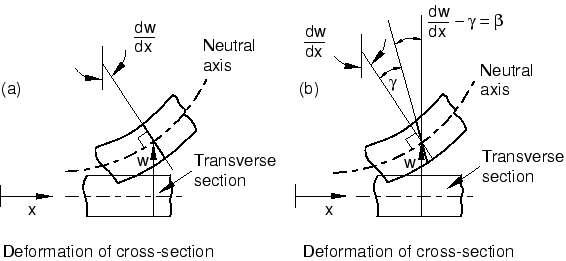

The inclusion of transverse shear deformation in plate-bending behavior is the main difference between thin and thick shell formulation. Thin-plate formulation follows a Kirchhoff application, which neglects transverse shear deformation, whereas thick-plate formulation follows Mindlin/Reissner, which does account for shear behavior. Thick-plate formulation has no effect upon membrane (in-plane) behavior, only plate-bending (out-of-plane) behavior.

Shear deformation tends to be important when shell thickness is greater than approximately 1/5 to 1/10 of the span of plate-bending curvature. Shearing may also become significant in locations of bending-stress concentrations, which occur near sudden changes in thickness or support conditions, and near openings or re-entrant corners. Thick-plate formulation is best for such applications.

Thick-plate formulation is also recommended in general because it tends to be more accurate, though slightly stiffer, even for thin-plate bending problems in which shear deformation is truly negligible. However, the accuracy of thick-plate formulation is sensitive to mesh distortion and large aspect ratios, and therefore should not be used in such cases when shear deformation is known to be small.

In general, the contribution of shear deformation becomes significant when ratio between the span of plate-bending curvature and thickness is approximately 20:1 or 10:1. The formulation itself is adequate for ratio down to 5:1 or 4:1. In that this ratio is dependent upon the projected span of curvature, shell thickness may be greater than the actual plan dimensions of a shell object.

Stiffness for pure-bending deformation

The statement that thick shells tend to be stiffer than thin shells applies only to the bending components of shells, and to models in which meshing is too coarse.

When meshing adequately captures bending deformation, thick-shell elements are more flexible because of the additional shear deformation that is not captured through thin-shell formulation. Given pure-bending deformation, however, the thin-shell element is slightly more accurate, therefore the thick-shell element may be stiffer for coarser meshes. This effect diminishes as the mesh is refined.

Stresses may be of greater concern than deflections. When shear deformation is expected to be important, we recommend the thick-shell element because it will better capture the stress distribution. This is the case not only for thicker shells, but also for regions near openings and other geometric discontinuities in which transverse shear deformation develops.

Leave a Reply

You must be logged in to post a comment.