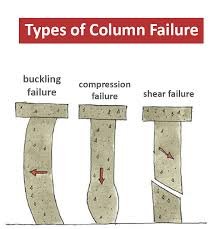

We know generally Columns are axially loaded members in structure. It carries compression force due to gravity loads of the structure. Column fails for different reasons. There are mainly three types of failures occur in columns. These are-

1.Compressive Failure

2.Buckling Failure

3.Shear Failure

Now let’s discuss about the failure types in details & reason of the failures.

1. Compressive Failure

Compressive failure is a failure occurs due to developed compressive stress more than allowable stress. It occurs for the material itself crushing or yielding not the column.Shorter and wider column normally fails under compression failure. Three factors are responsible for this issue. Number one is loading, number two is compressive strength of the materials & the third is the cross sectional area of the column.

7 Healthy Habits a Former Pro Bodybuilder Lives By tren hex bodybuilder roid bull naked- Overloading greater than the designed load (for which the column has been designed) on column can lead cause this failure.

- Due to poor concreting Compressive strength is found less than the designed for the column, it causes the failure.

- If above conditions safe then Cross-section is a factor if column fails. Provision of the cross-section less than the designed section(which would be adequate to bear the compressive stress) leads to this failure.

Prevention: Prevention way of this failure can be found in the reasons we discussed. We have to ensure that the column will not experience any overloading, the column is having designed compressive strength & the column is having adequate cross-section as per design.

2. Buckling Failure

Buckling failure occurs in long column(slender column) where the columns displace laterally or horizontally. Increasing of slenderness of column decreases load carrying capacity in such way that the column tends to buckle laterally or horizontally at mid-zone of its length (See figure).

Reason of this failure- Long column effect or Slenderness effect of the column may cause buckling failure. If column effective height is more than 12 times of least width (for circular column it’s diameter), then it’s called slender column or long column.

Prevention: For designing slender or long column special care must be taken as per codes & design guideline so that the column can resist itself from buckling. If possible better to increase least width of column to avoid slenderness.

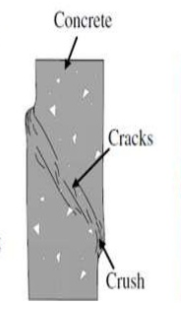

3. Shear Failure

Shear force tends to produce sliding failure on a material along a plane that is parallel or slightly parallel (diagonal) to the direction of the force. When shear force exceeds the shear capacity of column then this failure occurs.

Reason of this failure-

To resist shear force in RCC columns we have to provide shear reinforcement or tie bar or confinement bar. If these tie bars are not adequate to resist the developed shear in column then this failure will happen.

Prevention: RCC columns must be designed with required tie rebar for the proper confinement of main rebars. Design & selection of tie diameter & spacing is very important for proper shear resistance. For column design with main rebar and shear reinforcement (tie bar) you can check following ‘made-easy’ tutorial-

Leave a Reply

You must be logged in to post a comment.